| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

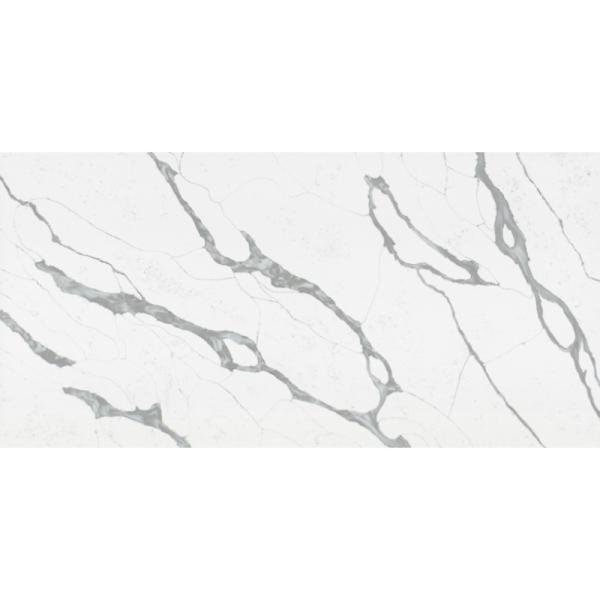

| Brand Name : | O-LAND QUARTZ |

| Model Number : | OLK1121 |

| Certification : | NSF/CE/SGS/GREEN GUARD/HPD |

| Price : | $$$ |

| Payment Terms : | 30% DEPOSIT,THE BALANCE PAID AGAINST THE BILL OF LOADING. |

| Supply Ability : | ++++ |

| Delivery Time : | ABOUT 30 WORKING DAYS AFTER RECEIVING THE DEPOSIT. |

OLK1121 - Quartz Slab Eco-Friendly And Healthy Applied To Cabinets

Description:

1. can be custom-made to specific sizes, shapes, and colors to meet diverse design requirements

2. innovative design possibilities in architecture and interior design

3. can be cut, polished and other processing according to demand

4. making it environmentally friendly and safe for human health

5. makes it simple to clean and maintain its aesthetic appeal

Quick Detail:

The typical manufacturing process for engineered stone involves the following key steps:

Raw Material Preparation:

Mixing and Compaction:

Curing and Finishing:

Quality Inspection and Packaging:

Specification:

| Technical Specifications* | ||

| TEST PERFORMED | TEST PROCEDURE | TEST RESULTS |

| Specific Gravity | ASTM C97 | 2.45gr/cm |

| Mohs Hardness | BS 6431 | 6-7 Mohs |

| Impact Resistance | 15-25cm for 1.2cm products | |

| TS EN 14617-9 | 35-60cm for 2cm products | |

| 80-175cm for 3cm products | ||

| Flexural Strength | TS EN 14617-2 | 40-70 N/m ㎡ |

| ASTM C880 | 6301 psi | |

| Abrasion Resistance | TS EN 14617-4 | 140-175mm |

| Water Absorption | TS EN 14617-1 | 0.1% |

| BS 6431-11 | 0.1% | |

| Flame Spread | ASTM E-84 | Class A |

| Chemical Resistance | ASTM D2299 | Only strong acids amd bases may alfect |

| BS 6431-18 | ||

| Resistance to Freeze and | ASTM C1026 | No change |

| Thaw Cycling | ||

| Modulus of Rupture | BS 6431-12 | 52.4 N/mm ㎡ |

| Thermal Shock Resistance | ASTM-C484 | No visible defects |

| Wheathering | ASTM G23 | No visible changes after 100 hours |

| *Test results may vary according to product properties. | ||

Advantage:

Artificial stone is a new type of environmental protection composite material, compared with traditional building materials such as stainless steel and ceramics, artificial stone has diverse functions, rich colors and a wider range of applications.

The solid surface material of artificial stone is combined with

resin and aluminum hydroxide in a special process, which releases

water molecules in the case of high temperature and heat, and has

the function of flame retardant and heat absorption.

Tested by the national authority, the ingredients contained are non-toxic, harmless, non-radioactive, environmental protection and health, and are truly green and safe.

Compared with other building materials, the toughness of the solid surface material of artificial stone is better, it is not easy to break, and the whole is dense without holes, leaving no chance for bacteria to multiply, touching the skin is warm, not easy to wear, hide dirt, decay and other advantages, it is an economic and durable good product.

|